The principles that underlie an EUV scanner are the same as for every optical scanner – but their execution is completely different.

1. Producing EUV light

A kind of inkjet nozzle produces forty thousand minuscule droplets of molten tin per second. As it falls, each droplet is shot twice by a laser. The first, relatively weak pulse deforms the droplet into a pancake; the second, much harder punch vaporizes it and creates a plasma, which emits EUV light in a fairly broad wavelength range. EUV optics (see step 2) around the plasma prefilter the light and concentrate it to a focal point located precisely at the border of the source and the machine. Inside the machine, the light is filtered again until what’s left is primarily 13.5-nanometre light.

Challenges: 1) Providing sufficient power, by a) efficiently converting the laser energy into EUV light and b) efficiently guiding the light to the scanner. 2) Making sure no debris damages the delicate collector. ASML uses a curtain of hydrogen for this.

2. Focusing EUV light

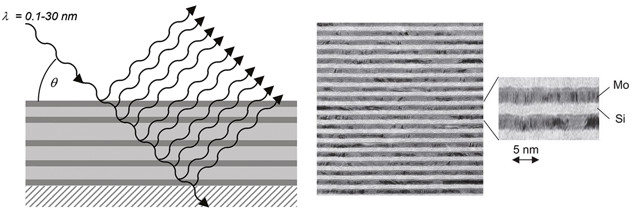

There are no lenses for EUV light, so EUV optics are reflective. There’s no material that can reflect a substantial portion of the EUV light in a single layer. But because multiple layers can reinforce each other’s reflections, it’s possible to make reasonably efficient EUV mirrors. These mirrors are crafted by alternating nanolayers of molybdenum (which partially reflects EUV light) and silicon (which is largely transparent to EUV). The theoretical maximum reflection is 74 per cent; the record is 70.3 per cent.

Challenge: to reflect the most possible light, given that 30 per cent is lost at each mirror. That adds up quickly for multiple mirrors, plus the mask (step 3) and the spectral filter. These optics must also stay clean, despite the constant EUV bombardment and contamination by residual gases.

3. Making patterns with EUV light

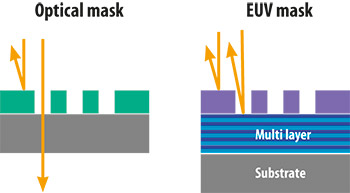

EUV absorption also wreaks havoc on the mask. Light passes through a typical optical mask, but for EUV that would mean an unacceptably high loss of light. So like the optics, the mask is reflective: in essence, it’s a multilayer mirror with an absorbent layer into which the desired patterns have been etched.

Challenge: the tiniest flaws can be printed and thus produce unusable chips. But that isn’t a problem that ASML addresses. The Veldhoven company is concerned with keeping the mask clean, and it’s developed a pellicle – a thin-film dust cover – to protect its EUV masks. Debris that lands on the pellicle will be out of focus and thus not printed.